Test Stands AND Aircraft PRODUCTS for aerospace applications

Chant Engineering has had a long history of designing and manufacturing custom test stands and aircraft products for aerospace, aviation, military and industrial applications.

held to higher standards

Over 55 Years of Testing Machinery You Can Trust

Chant Engineering is known as a leader in manufacturing heavy-duty testing equipment for the aerospace industry.

Chant Engineering’s typical test stand capabilities include:

Pressure

Flow

RPM

Temperature

Dynamic

Fatigue

Position

Force

Torque

Chant is accredited and certified to the following industry standards:

- ISO 9001:2015

- AS9100D

- ISO/IEC 17025:2017 Accredited

TEST STANDS FOR AEROSPACE APPLICATIONS

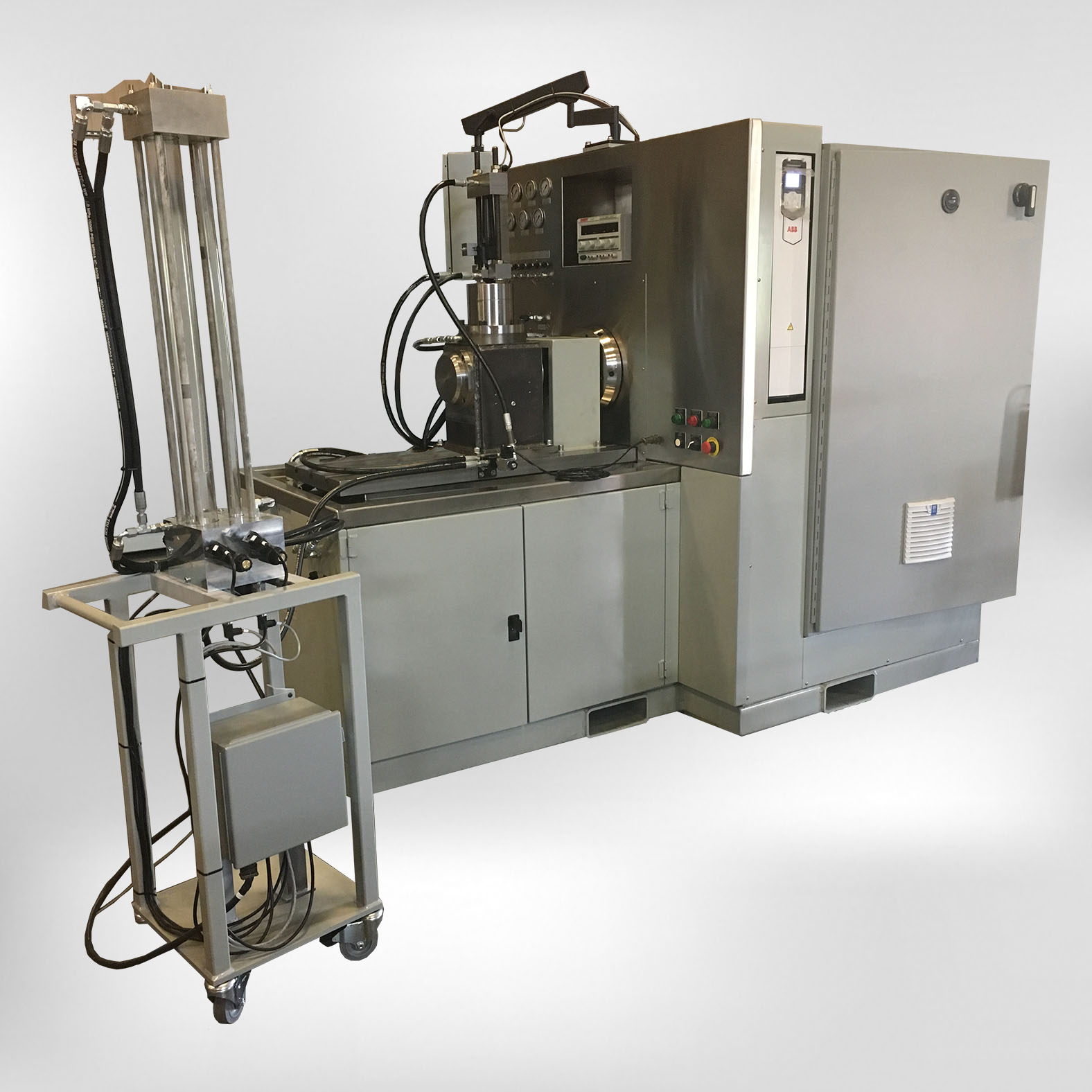

Hydraulic Servo Valve Torque Motor Test Stand

Model 840101

Chant Model 840101 is a Hydraulic Servo Valve Torque Motor Test Stand designed to test the servo valve torque motor assemblies on aircraft servo valves, which is a sub-assembly of the servo valve.

F-15K Servo Valve Test Stand

Model 9342-01

Chant Model 9342-01 is a F-15K Servo Valve Test Stand designed to test 3 and 4-way electro-hydraulic and proportional valves. This unit allows operators to test in fully automatic, semi-automatic and manual modes.

This machine test part NSN 4920-01-591-3982

F-15 Speed Calibrati0n Test Stand

Model 854301

Chant Model 854301 is a Speed Calibration Test Stand that is designed to verity the F-15 secondary power system governors and switches that are being dynamically calibrated.

Fatigue, Cycle & Static Shaft Test STand

Model 838601

Chant Model 838601 is a Fatigue, Cycle & Static Shaft Test Stand designed to perform dynamic and static testing of power take-off shafts for aerospace and military customers. One test dynamically fatigues the shaft and one test is for the static torque.

Liquid coolant pump test stand

Model 10502-01

Chant’s Model 10502-01 Liquid Coolant Pump Test Stand is designed to test aircraft liquid cooling pumps, heat exchangers and valves. A fully automated test stand with data acquisition software and touchscreen HMI controls for all tests.

Nozzle Actuator Test Stand

Model 10552-01

Chant’s Model 10552-01 Nozzle Actuator Test Stand is designed to accommodate up to four types of actuators plus a feedback transducer.

This unit provides two operator touch screens to set up test parameters and test multiple devices in each test sink.

Fuel Flow Test Stand

Model 8420

Chant’s Model 8420 Fuel Flow Test Stand is designed to dynamically test and certify aircraft in-flight refueling equipment.

The test stand consists of a 2,000 gallon jet fuel tank along with the necessary valves, pumps, manifolds and operator controls.

Fuel Oil Test Stand

Models 10123-01 & 10123-02

Chant’s Model 10123-01 and 10123-02 is a Fuel Oil Test Stand System designed to manually test aircraft lube components with MIL-PRF-23699 fluid in accordance with the required specifications.

Hydraulic Test stands

Model 11037

The Chant Model 30387 Hydraulic Test Stands project includes two separate test stands. These hydraulic test stands are designed to test various specified hydraulic components and other components as well. They test any component that can use the same hydraulic fluid and has requirements that are within the capabilities of the test stands. These hydraulic test stands are designed and manufactured in accordance with the information supplied in addition to good commercial practice.

Hydraulic Test stands

Model 11401

This test structure comprises of two vertical parallel channels with cross members attached top and bottom to form a rectangular assembly. Two hydraulic cylinders, one on each side, are mounted within the channels with their piston rod ends connected by a movable cross member. Simultaneous extension or retraction of the cylinders will cause the movable cross member to move up or down.

Diesel Test stands

Model 11594

This proposal is in response to Solicitation SPM4A8-12-R-0054 for two hydraulic test stands and related work to test various specified hydraulic components. These hydraulic test stands test other components as well. They can test any component that can use the same hydraulic fluid and has requirements that are within the capabilities of the test stands. These hydraulic test stands are designed and manufactured in accordance with the information supplied in addition to good commercial practice.

Hydraulic Test stands

Model 30135

The test system consists of a single Hydraulic Power Unit (HPU) and two test stations. The HPU has a single electric motor of 300 hp that will drive two hydraulic pumps. Each hydraulic pump is capable of providing approximately 73 gpm, and is capable of operating at up to 5000 psi.

Fuel pump test stand

Model 10435-01

Chant’s Model 10435-01 Fuel Pump Test Stand is designed to manually test aircraft fuel components with MIL-PRF-7034E, Type II. This test stand meets the requirements of NEC, Class I, Division I, Group D.

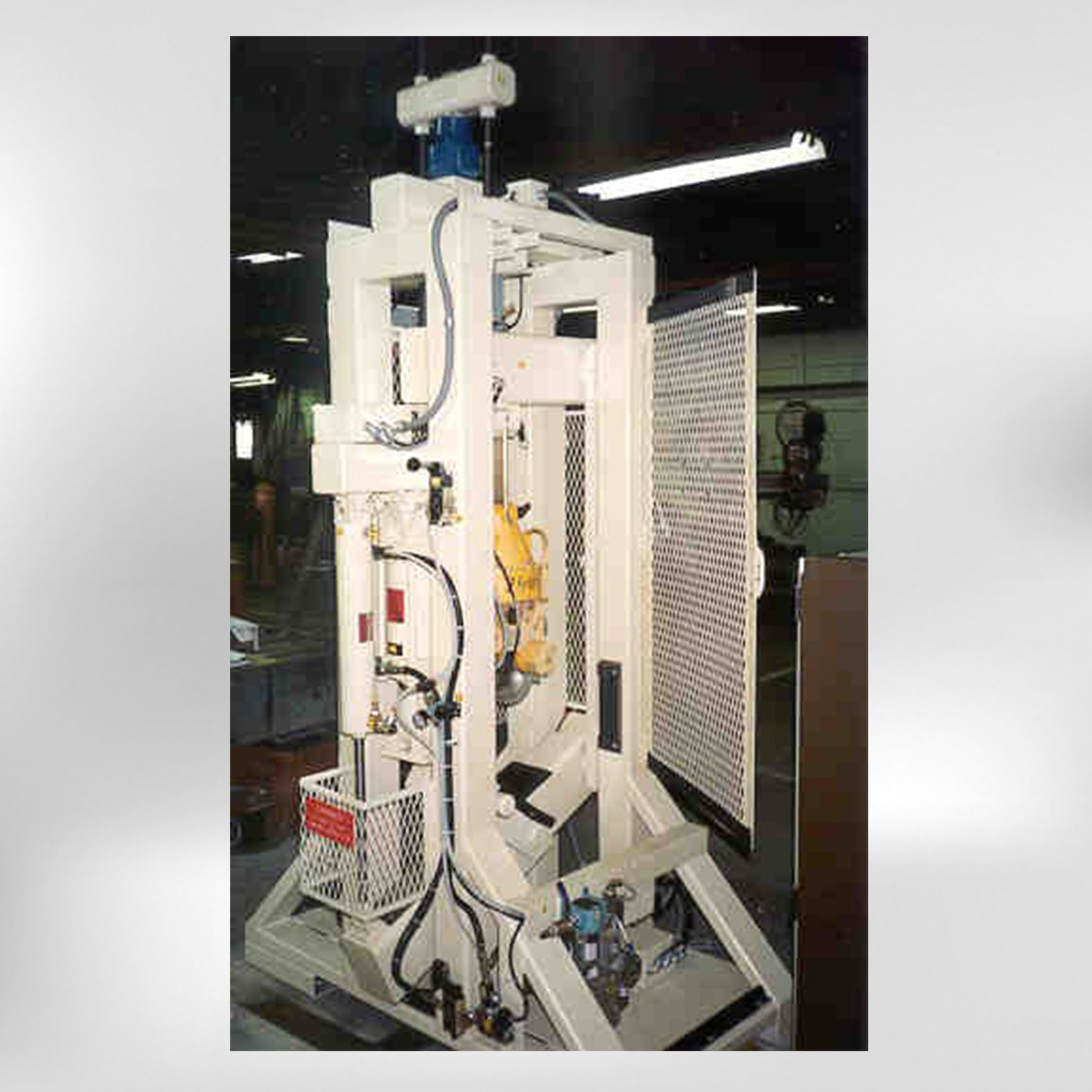

helicopter cargo hook test stand

Model 949001

Chant’s Model 949001 Helicopter Cargo Hook Test Stand is a hydraulically controlled, semi-automated machine designed to perform tension testing up to 75,000 lbs. and electrical operation of helicopter cargo hooks in a production based military depot environment.

Cargo hook Test Stand

Model 31312

The Chant Model 31312 Cargo Hook Test stand has several devices that are calibrated to NIST standards but will require periodic calibration during the life of the test stand. All of these devices can be calibrated without having to remove them from the test stand. The devices requiring calibration are the pressure transducer, load cells, and DC voltage. In order to operate the test stand, it must be powered on with the test stand program running.

pneumatic Test Stand

Model 94300601

Chant’s Model 94300601 Pneumatic Test Stand is used to test pneumatic components used in military aerospace applications.

Pneumatic Component test stand

Model 10356

Chant’s Model 10356 Pneumatic Component Test Stand is designed to test aircraft hydraulic and pneumatic components such as engine-drive hydraulic pumps, electro-hydraulic flight control assemblies, double acting hydraulic cylinders, pneumatic and hydraulic relief valves, hydro-pneumatic accumulators and other components.

This machine test part NSN 4920-01-606-2165

Universal Automatic Hydraulic Test Stand

Model 9736909

Chant’s Model 9736909 Universal Automatic Hydraulic Test Stand is used for testing aircraft control components.

Display monitors show pressures, flows, speeds, torques, and temperature in order to accurately measure parameters of the units under test (UUT).

UNIVERSAL HYDRAULIC Test Stand

Model 97371008

Chant’s Model 97371008 Universal Hydraulic Test Stand is designed to test aircraft control components.

Located along the panel of the console are all the necessary controls to start the multiple hydraulic pumps and control pressures and flows to all the ports.

The unit features a wide test bench, two monitors and CPU, splashguard, high variable speed drive, a test sink with pressure and return test ports, DC power connection, temperature control and sump.

F-16 Servo Valve TEST STAND

Model 8931-01

Chant’s Model 8931-01 F-16 Servo Valve Test Stand when connected to an external hydraulic power sources (5,000 psi, 2 gpm) is designed to test and record characteristics of 3 and 4-way electro-hydraulic servo valves.

This test stand can perform the following tests: proof pressure, external leakage, no-load flow pot, linearity, symmetry, hysteresis, overlap and internal leakage.

Static Hydraulic Test STand

Model 10024610

Chant’s Model 10024610 Static Hydraulic Test Stand is used for testing T-38/F-5 aircraft components.

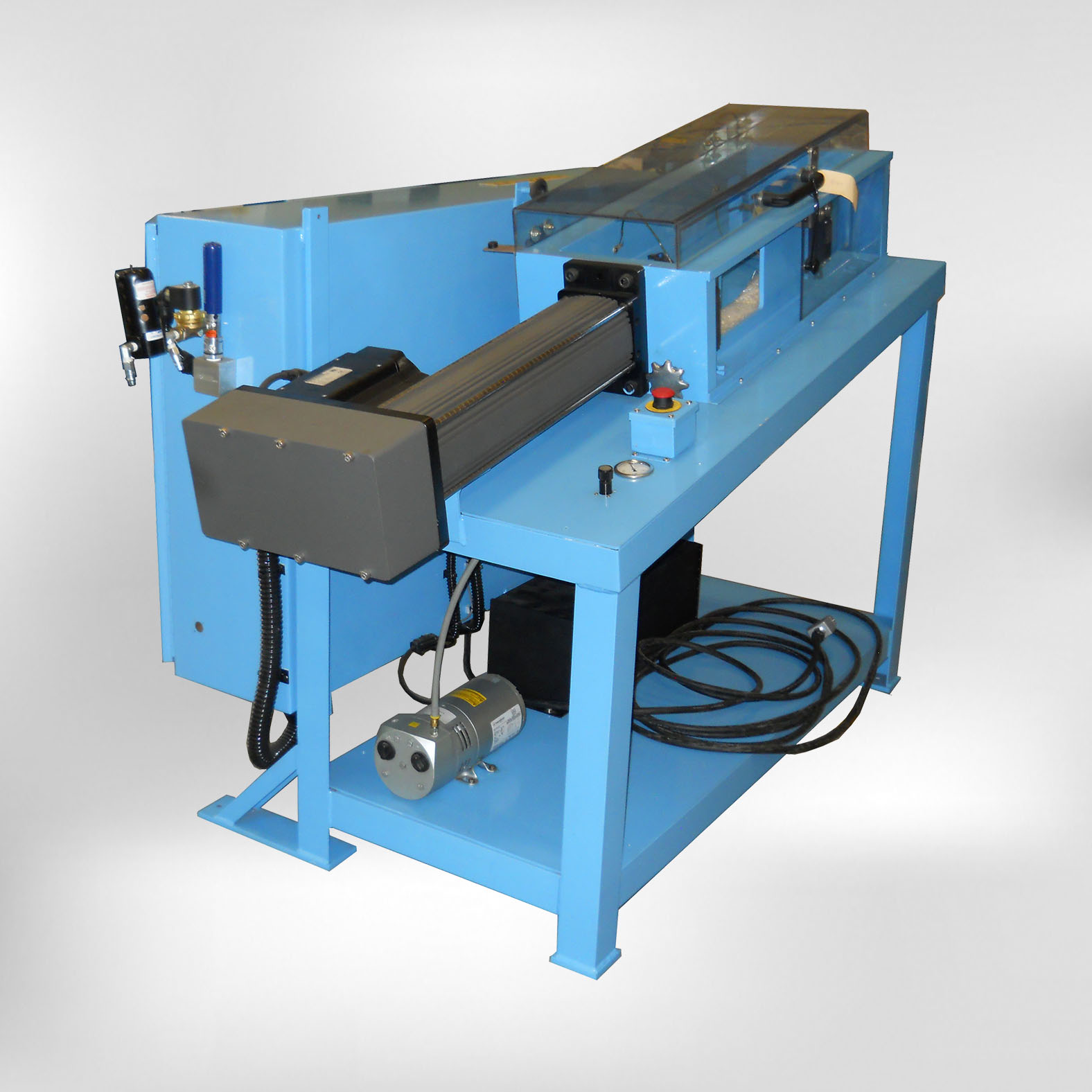

Servo-Linear Component Test Stand

Model 30387

Chant’s Model 30387 Servo-Linear Component Test Stand includes a Rotating Component Test Station, Pump Control and Distribution Manifold with custom Hydraulic Power Unit (HPU).

This system tests a multitude of aircraft hydraulic components, such as: hydraulic servo actuators, mainifolds, accumulators, hydraulic pumps, hydraulic motors and integrated hydraulic power units.

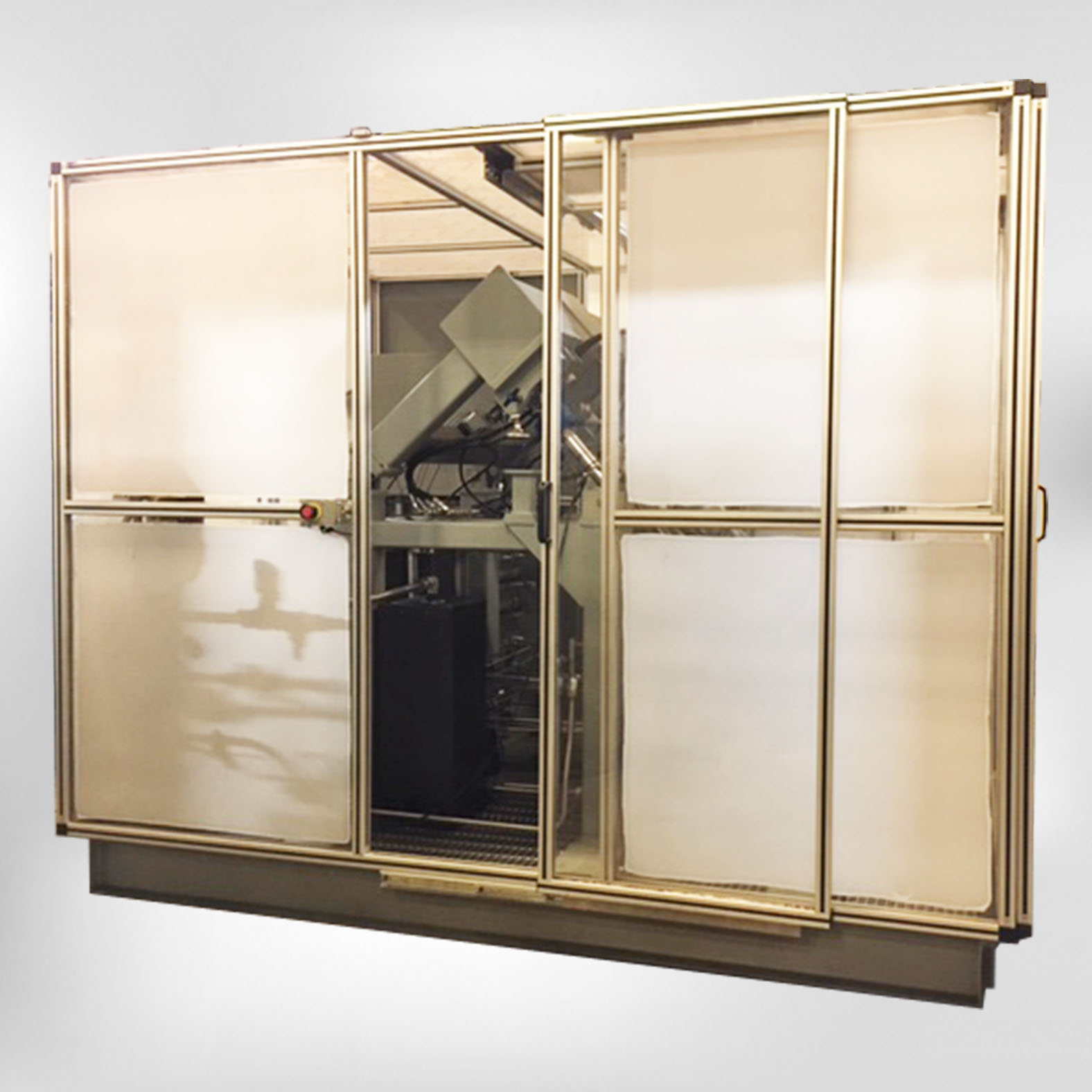

Hyraulic Test Stands

Model 11806

The Chant Model 11806 Hydraulic Test Stands project includes 3 separate test stands. It is comprised of two parts – the test fixture for mounting the actuator and the control station. These two parts integrate to form one complete test stand with the mounting fixture at a convenient working height within a transparent polycarbonate safety enclosure, and the control station adjacent with a computer screen at convenient height and a work table in front.

The control station is built from standard EIA enclosure modules installed within a vertical cabinet with louvered doors. It includes the computer system, programmed using LabVIEW, with a touch screen monitor, servo amplifiers, power supplies and all electronics necessary for a complete control system. A hard wired power on/off switch with fuses is also provided.

Hydraulic Test stands

Model 11037

The Chant Model 30387 Hydraulic Test Stands project includes two separate test stands. These hydraulic test stands are designed to test various specified hydraulic components and other components as well. They will test any component that can use the same hydraulic fluid and has requirements that are within the capabilities of the test stands. These hydraulic test stands are designed and manufactured in accordance with the information supplied in addition to good commercial practice.

FUEL COMPONENT TEST STAND

Model 30499

The Chant Test Stand model 30499 is designed to test Fuel Accessories of TF34 & F404 engines. It can also be used to test any other fuel components which can fit within the hydraulic and electrical capacity of the test stand. It is designed to use fluid supplied by external Hydraulic Power Unit (HPU) which in this case is a centralized fluid supply and return system in the building. Because of the fluid properties which are hazardous in nature, this test stand is designed and rated for Hazardous area classified per ClassI, Division-II.

HYDRAULIC Component TEST STAND

Model 30511

Chant Model 30511 Hydraulic Component Test Stand (HCTS) is two operator stations powered by one central hydraulic power unit with heating and cooling equipment. Test stations are independently controlled for testing operations. This test stand is used for testing hydraulic valves, high-flow and low-flow relief valves, hydraulic actuators, motors, accumulators, flow control valves, and miscellaneous other hydraulic or hydro-pneumatic components used by the Navy.

.

DAMPER CYLINDER TEST STAND

Model 30821

The Chant Model 30821-01 Damper Cylinder Test stand has several devices that are calibrated to NIST standards but will require periodic calibration during the life of the test stand. All of these devices can be calibrated without having to remove them from the test stand. The devices requiring calibration are pressure transducers, load cell, linear transducer and flow meter. In order to operate the test stand, it must be powered on with the test stand program running.

NOSE WHEEL STEERING ASSEMBLY TEST STAND UPGRADE KIT

Model 30787

The upgrade kit consists of a new HPU with touchscreen and automatic pressure control, printer, software and all new hydraulic and electronic components throughout the entire system. The input and output shaft have a torque cell and there is an absolute encoder to measure input and output angles. The operator controls are recipe driven semi-automatic with step by step testing of the UUT. The upgrade kit has complete data acquisition of each test and test certificates and plots can be printed for any test. Unit is delivered, started-up, training and documented.

AIRCRAFT PRODUCTS

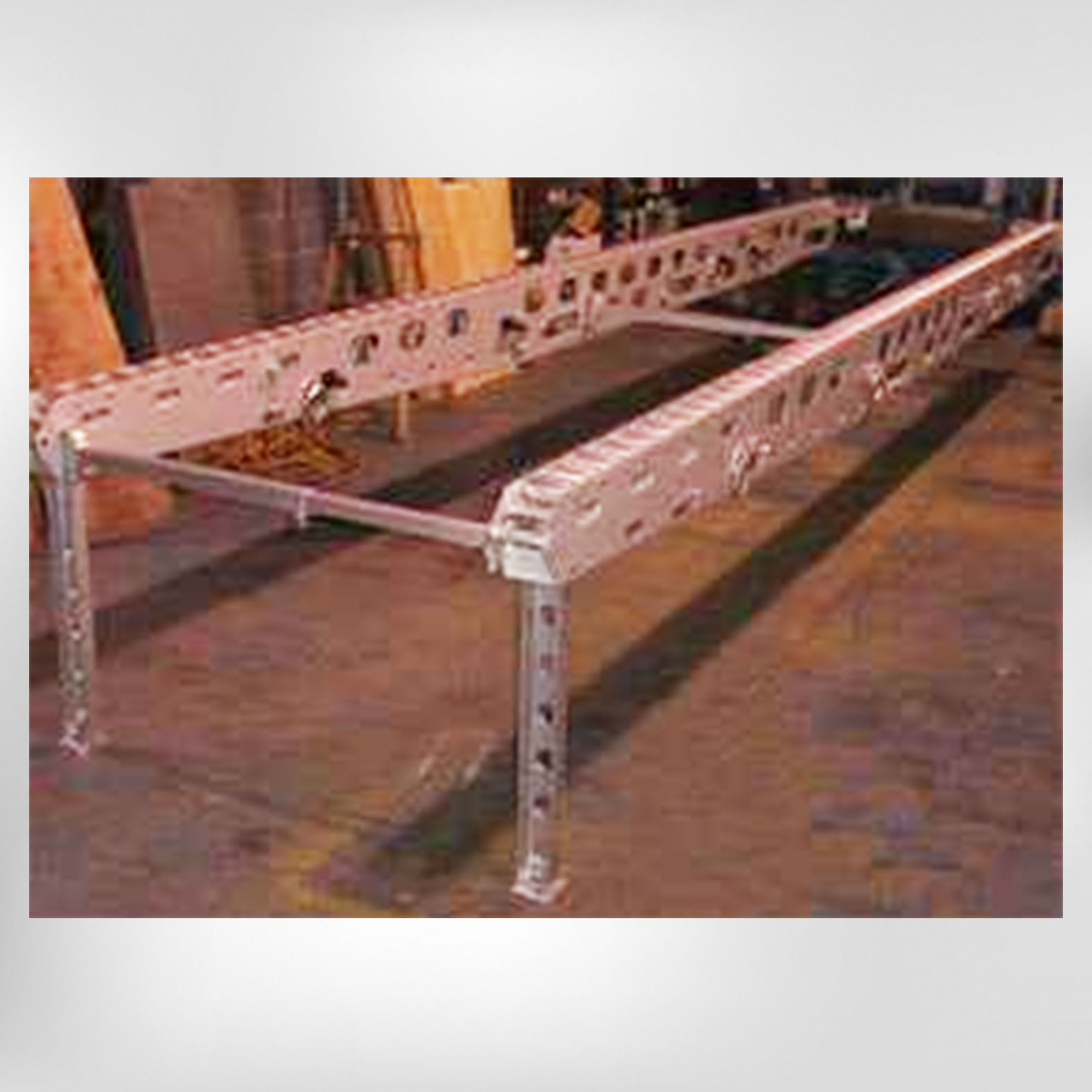

V-22 Cargo Rails

P/N 9263 ECRS V-22

A custom V-22 Extended Cargo Rail System (ECRS) is used on aircrafts where it is not possible to load the airplane via conventional methods.

Diesel Engine Driven Portable Hydraulic Test Cart

Model 10008

Chant’s Model 10008 Diesel Engine Driven Portable Hydraulic Test Cart is designed with a two-system hydraulic pumping unit to check the operation and performance of aircraft hydraulic systems.

It is a portable and self-contained unit, which provides functional testing on the aircraft.

Nitrogen service carts

Model 30165

NSN 3655-01-517-9308

P/N 1317AS100-2

Chant’s Nitrogen Service Units are manufactured using a structural steel frame suitable to hold the required components. Carts have provisions for the accumulation, containment, and dispensing of nitrogen (‘gas’) at pressures up to 3,500 psi. Nitrogen is dispensed into aircraft and aircraft support equipment, or used to pressurize those items.

Each unit has six nitrogen bottles having a capacity of 340 cu ft of nitrogen.

Deployable Hydraulic Lift (dehl)

Model 963401 – DeHL

The Deployable Hydraulic Lift (DeHL) is an unloading device designed to work with the Military Halvorsen 25K Loader.

V-22 Engine Rinse Wand

V-22 Engine Rinse Wand

Chant’s V-22 Engine Rinse Wand is used to fresh water rinse the V-22 engines during shipboard/sale air use.

V-22 Snatch Block Pulley

NSN 1680-01-566-5137

P/N 901-320-546-101

The Chant Engineering V-22 Snatch Block Pulley is a field proven design that is easy to use by the warfighter.

Helicopter test equipment

NSN 4240-01-029-7148

P/N D7974

Chant Engineering is a preferred vendor for Helicopter Test Equipment.

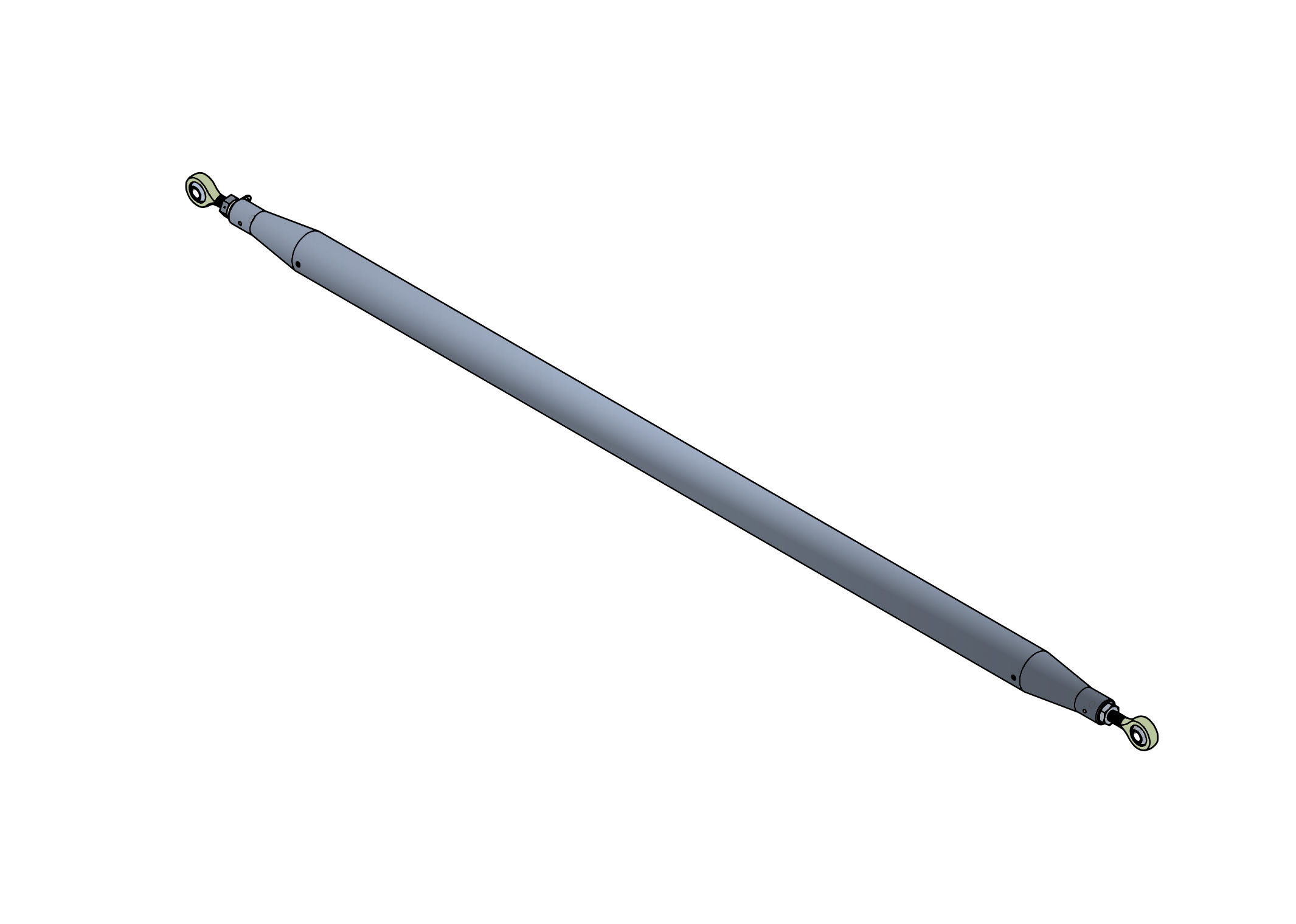

Airplane Strut

Part Number 77272-901-320-402-101

Model 14012

This strut 901-320-402-101 is used on the V-22.